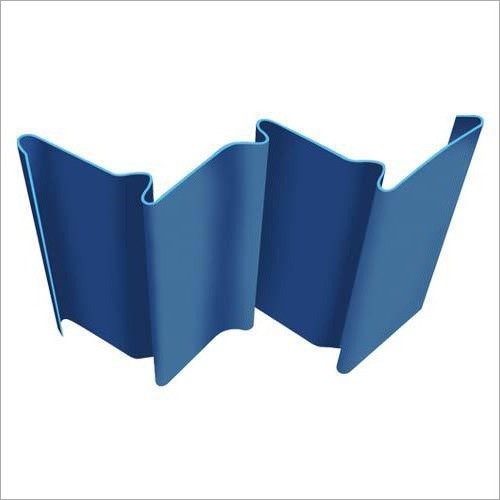

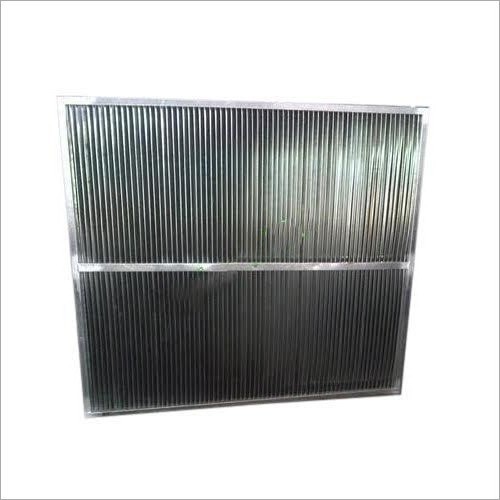

PVC Mist Eliminators

Price 5000 INR/ Unit

PVC Mist Eliminators Specification

- Humidity %

- Suitable for high humidity applications

- Pressure Range

- Standard atmospheric to 3 bar

- Maintenance Type

- Low maintenance

- Filtration Property

- High-efficiency mist separation

- Dust %

- Up to 98% mist separation efficiency

- Dust

- Removes liquid droplets, fine mists

- Frequency

- 50/60 Hz Hertz (HZ)

- Vaccum Range

- -500 mm WC to atmospheric pressure mpa

- Hole Size

- 2-5 mm chevron spacing Millimeter (mm)

- Flow Rate

- Up to 40000 m/hr or customized

- Control System

- Optional/manual or automated as required

- Application

- Chemical industries, gas scrubbing, process ventilation

- Efficiency (%)

- 96% to 99% mist removal

- Connectivity Type

- Standard duct flanges or custom

- Features

- Corrosion resistance, lightweight, easy to install

- Output

- Clean air free from visible mist

- Installation Type

- Horizontal / Vertical setup

- Noise Level

- < 70 dB(A) db

- Filters

- Chevron / Blade Type PVC Fill Packs

- Color

- Grey / White / Blue

- Material

- MS, SS, GI, PVC

- Automatic Grade

- Manual / Semi-Automatic

- Power

- Depends on system design

- Voltage

- 220-440V Volt (v)

PVC Mist Eliminators Trade Information

- Minimum Order Quantity

- 25 Units

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 4 Days

- Main Domestic Market

- All India

About PVC Mist Eliminators

The PVC Fog Eliminators that brought by us is essentially used in Air Washer or Cooling Pinnacle for holding water drops and fog in the hot stream, accordingly, keeping them from getting away from the cooling tower. This kind of eliminator is created from first in class aroused iron in thickness from 1mm to 2.5mm with redid size. Easy to introduce, and correspondingly steady, the PVC Fog Eliminators can be profited in various sorts and wraps up according to prerequisite.

Other Details:

Thickness: 1mm to 2.5mm

Size: Customized

Usage: Air Washer

Feature: Durable

Product details

|

Best recommended pitch |

29.5 mm |

|

Eliminators Width |

170 mm |

|

Country of Origin |

Made in India |

|

Material |

Plastic |

|

Color |

Red,blue,green |

|

Filter Medium Material |

Fiberglass |

Corrosion-Resistant Performance for Challenging Environments

PVC Mist Eliminators exhibit exceptional corrosion resistance, making them suitable for handling aggressive fumes and vapors encountered in chemical industries and gas scrubbing applications. The use of UV-stabilized PVC ensures long-lasting durability, even in environments with high humidity or exposure to ultraviolet light, providing more than 15 years of reliable service under recommended use.

Custom Configurations for Varied Industrial Needs

Whether the requirement is for horizontal or vertical installation, standard or high-efficiency mist removal, or specific capacities up to 40,000 m/hr, these mist eliminators can be customized for process and dimensional needs. Options include various material selections, removable panels for easy cleaning, and connectivity via standard duct flanges or bespoke solutions to meet unique operational demands.

Energy-Efficient, Quiet Operation with Minimal Maintenance

Engineered to operate with minimal energytypically only for auxiliary fansthese systems maintain noise levels below 70 dB(A) and feature low maintenance requirements thanks to accessible removable panels and robust construction. Smooth-surface fill packs facilitate high-efficiency mist separation at low pressure drop, keeping operational costs and downtime to a minimum.

FAQs of PVC Mist Eliminators:

Q: How does the PVC Mist Eliminator achieve high mist separation efficiency?

A: The PVC Mist Eliminator utilizes advanced blade-type or chevron fill packs with optimized spacing (25 mm) to trap and separate liquid droplets and fine mists from exhaust gases. Its smooth surface and customizable packing density help minimize pressure drop while maintaining 9699% mist removal efficiency.Q: What industries commonly use PVC Mist Eliminators?

A: These mist eliminators are widely used in chemical processing, gas scrubbing, industrial exhaust systems, and air pollution control applications. Their corrosion resistance and efficient mist removal make them ideal for environments with high humidity and exposure to corrosive vapors.Q: When should the removable panel of the mist eliminator be accessed for cleaning?

A: It is recommended to access the removable panel periodically, based on the process load and mist concentration, to ensure optimal performance. Regular inspection and cleaning help maintain high separation efficiency and prolong the equipments design life of over 15 years.Q: Where can the PVC Mist Eliminator be installed?

A: The equipment is suitable for both horizontal and vertical installations. It can be integrated into existing ductwork using standard or custom duct flanges, supporting various layouts in industrial settings according to customer requirements.Q: What are the benefits of using UV-stabilized PVC in mist eliminators?

A: UV-stabilized PVC provides increased resistance to ultraviolet degradation, enhancing longevity and performance in outdoor or UV-exposed installations. This feature supports long-term durability, maintaining integrity even under challenging environmental conditions.Q: How does the mist eliminator contribute to environmental compliance?

A: By achieving up to 99% mist removal, the PVC Mist Eliminator ensures exhaust air is free from visible mists, enabling compliance with stringent environmental pollution control norms and helping facilities meet regulatory standards effectively.Q: What customization options are available for PVC Mist Eliminators?

A: Customers can specify process parameters, dimensions, flow rates (up to 40,000 m/hr), material grades, control types (manual or automated), and whether to include ventilation fans. The design is adaptable to meet unique operational, capacity, or installation needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Water Eliminators Category

Curved PVC Mist Eliminators

Price 5000 INR / Piece

Minimum Order Quantity : 25 Pieces

Material : PVC

Cooling Tower PVC Mist Eliminator

Price 5000 INR / Unit

Minimum Order Quantity : 25 Units

Material : MS, SS, GI, PVC

GI Mist Eliminator

Price 5000 INR / Unit

Minimum Order Quantity : 25 Units

Material : MS, SS, GI, PVC

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry